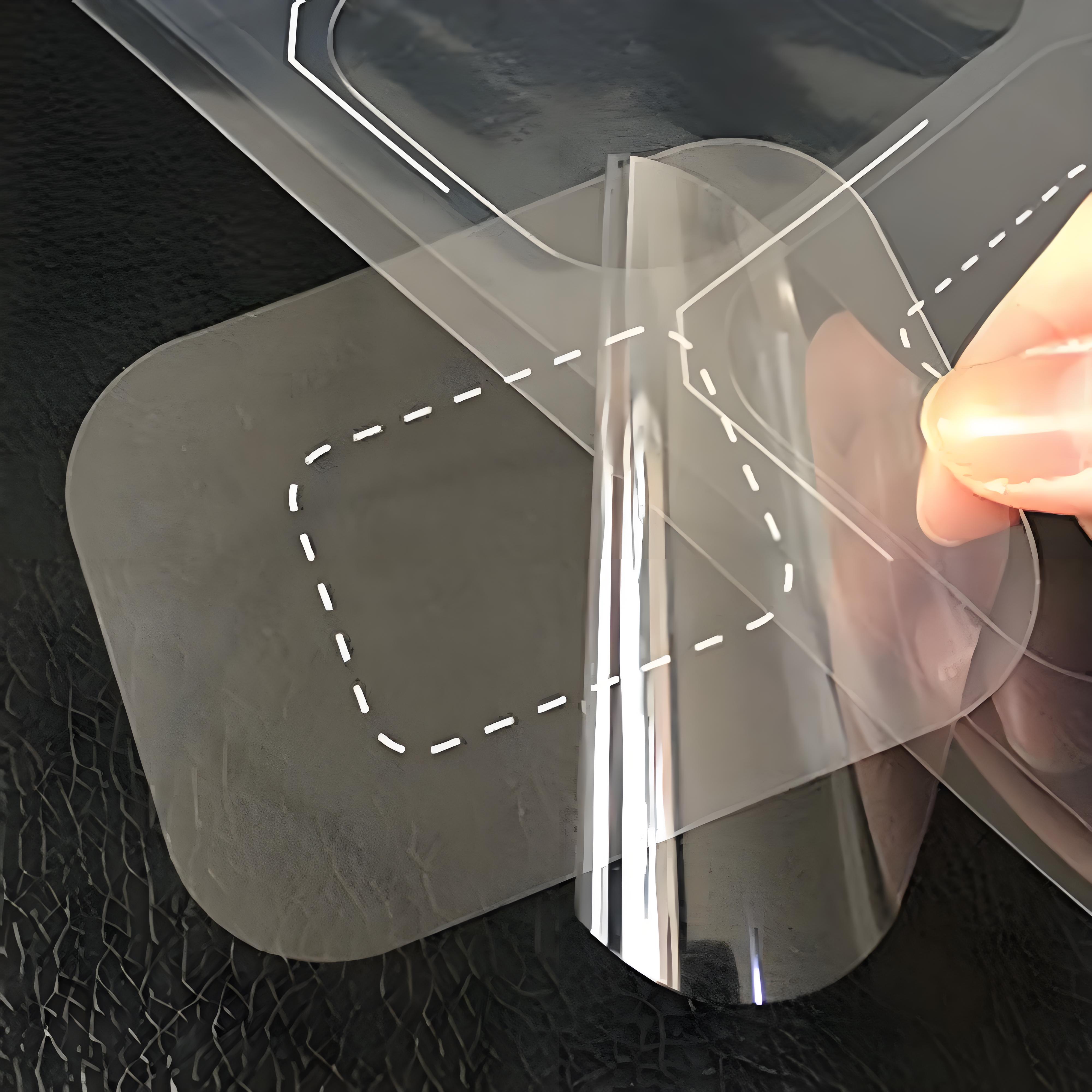

Protective film for diffuser and die cutting

Mar 10,2025

PET protective film is widely used in the surface protection of various products, so whether the role of different product protective film is the same? PET protective film is the simplest polymer organic compound of special polyethylene plastic film. Can protect the product from scratch, dust, corrosion, antistatic and so on.

First, the following describes the different role of PET protective film in the unused industry:

1, electronic industry: used for mobile phone screen, computer display dust and scratch.

2, screen printing industry: aluminum plate, copper plate, sign surface protection

3, liquid crystal industry: backlight plate, conductive film switch, touch screen film, LCD liquid crystal display is not polluted, scratched, collision.

4, plastic products: PVC plate, acrylic plate, instrument cover, mobile phone case, dust proof.

5, glass process: glass painting, painting, engraving, etc. are not scratched.

Second, the characteristics of PET mesh silicone protective film:

1, there are many holes on the surface of the mesh protective film, the air permeability is very good, the effect after adhesive is very beautiful, no bubbles.

2, no residual glue, rubber surface flat die-cutting without colloidal particles.

3, easy die cutting, suitable for the processing of electronic products.

4, the high light smooth surface has adsorption performance, automatic elimination of bubbles.

5, easy to peel.

6, washable, can be repeated application.

7, PET protective film has good light transmission, the better the light transmission, the better the quality.

8, the hardness of the surface of the PET protective film represents the degree of scratching on the surface of the product, the harder the protective film, the product is not easy to scratch.

Third, applicable product channels:

1, LCD, mobile phones, game consoles, TVS and other panel protection.

2, LCD template process and factory protection.

3, optical film engineering protection.

4, die cutting, diffusion sheet processing.

Related News